Optimel Schmelzgußtechnik debuted its newly developed technology at Productronica 2019 in Munich, Germany in November.

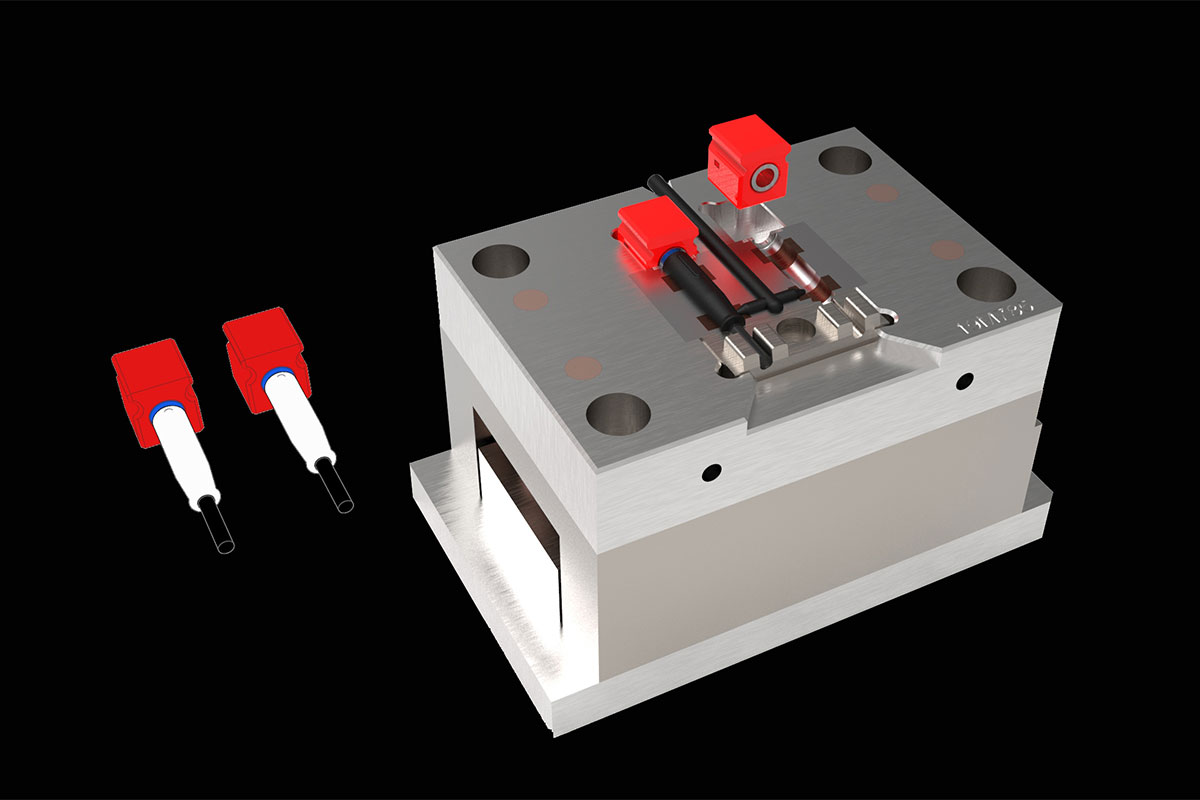

The innovative technology combines traditional low-pressure moulding processing with induction heating, in a single and stable process step. By doing this an impermeable bond to metal parts can be achieved with standard hotmelt encapsulation resins.

Previously, to achieve a strong bond with metal materials, additional processes needed to be undertaken, which meant additional costs. The new technology benefits users by creating better efficiency, removing the chance of errors as well as cost reduction.

The technology relies on designing project-specific tooling with an inductor integrated to target the contact area of the hotmelt to the metal, hence creating the watertight bond.

Fields of application include automotive, sensor, printed circuit boards and cable manufacturing, where an impermeable bond to metal is required.

With more than 44,000 international visitors each year to Productronica, a large audience was able to take the opportunity to see Optimel’s exciting technology first hand.

Along with the new technology Optimel also showed their new branding and machine series names, to reflect the flexibility by modularity theme running through their equipment line-up.

Should you have interest in learning more about the technology, and seeing if it is right for your requirements don’t hesitate in contacting Tarapath, where a representative will be more than happy to answer any questions.