People often ask, “Do you have experience over-moulding xyz connector”? More often than not the answer is no.

The reason for this is the innumerable amount of connector types out there. Having said, sometimes the answer is yes.

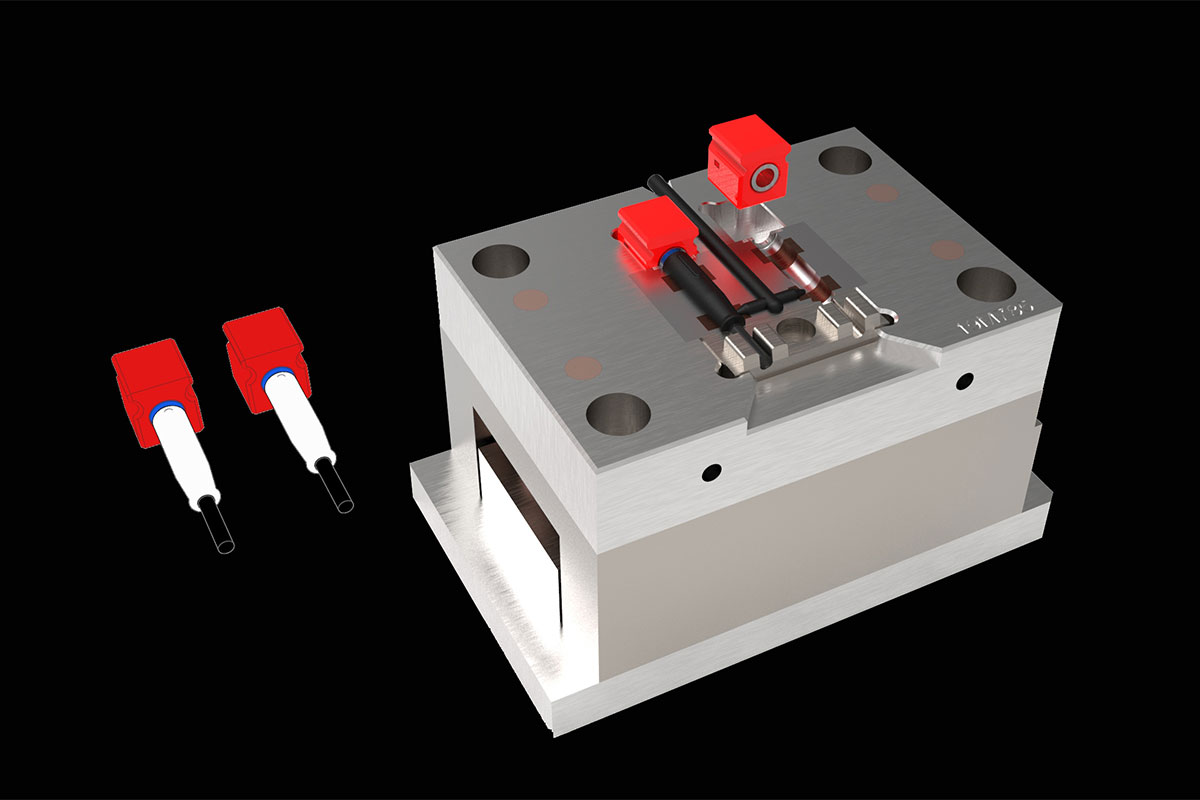

Moulding over connectors and onto cables is the most common type of project utilising low pressure moulding technology. In general terms around 70% of the projects Tarapath undertake have some type of connector to be considered in the design and implementation of tooling.

Generally, the connector is terminated on the end of a cable, but can often be part of a PCBA. Each type presents its own challenges, whether it be apertures in the connector, or alignment of the connector in the tooling. Whatever the case, the key is precise tooling to ensure a quality, consistent moulding. Usually, a simple one-step process is all that is required to protect a connector and its terminations from environmental factors.

Over-moulding a connector has big upside. The benefits include:

- Superior waterproofing capability

- Improved aesthetics over heatshrink boots

- Improved strain relief

- The ability to brand the part with logos and markings

If you have a project where over-moulding connectors is potentially a solution to your design problem, speak to Tarapath to get the complete picture.